The industrial sector is undoubtedly one of the busiest and most lucrative industries in the world. It’s responsible for producing essential goods and materials that are used in various sectors, such as construction, manufacturing, and transportation. With its high demand, it is not surprising that many businesses invest heavily in industrial machinery and tools to increase their production efficiency.

Industrial machinery and tools come in different types and purposes, which means they’re versatile and can help businesses in various industries. However, these tools are not only exclusive to large-scale factories and production plants. You can also find them in small workshops, where their efficiency and precision can make a significant difference.

What Are the Examples of Industrial Machinery?

If you’re exploring the essential workshop equipment to boost your business operations, you need to carefully consider your options and select the tools that will best suit your needs. Some may be more cost-effective for your business, while others may require more significant investments but offer better long-term benefits.

Sheetmetal Fabrication

One of the most commonly used industrial machinery types is sheetmetal fabrication equipment. These tools are used to shape, cut, and form metal sheets into various shapes and sizes for different purposes. They’re widely used in manufacturing vehicle bodies, building materials, appliances, and even furniture.

They consist of a range of tools, including shears, press brakes, rollers, and laser-cutting machines. Their precise and efficient performance makes them a staple in the metalworking industry, where accuracy is crucial and time is of the essence.

Woodworking Machinery

Similar to sheetmetal fabrication, woodworking machinery is also a widely used type of industrial equipment. These tools are used for cutting, shaping, and forming wood for various purposes, such as building furniture, cabinets, and other wooden structures.

This kind of workshop equipment can range from simple hand tools like saws and chisels to more complex machinery like routers, planers, and lathes. The former is more suitable for smaller workshops and DIY projects, while the latter is commonly used in larger-scale manufacturing operations.

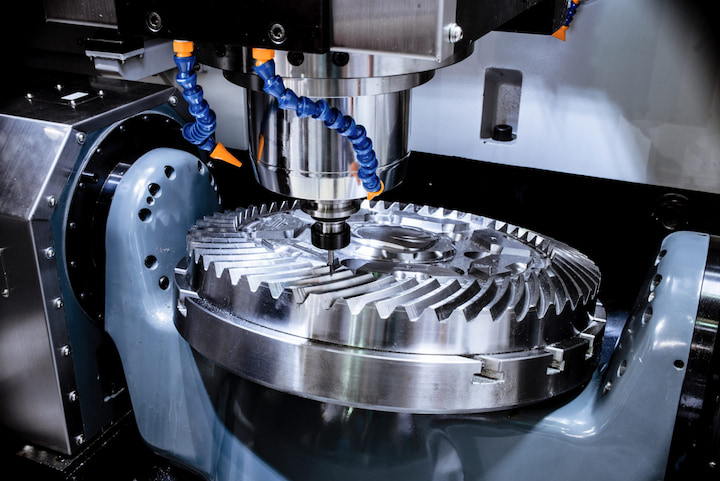

CNC Machines

Computer Numerical Control (CNC) machines are a type of industrial machinery that has revolutionized the manufacturing industry. They use computer programs to control and automate the production process, resulting in highly accurate and efficient results.

Their ability to produce complex shapes and intricate designs with minimal human intervention has made them an invaluable asset in the manufacturing world. The use of CNC machines has not only increased productivity but also reduced errors and waste in production. When coupled with advanced software and technology, they can truly create wonders in the production process.

Tube and Pipe Benders

More often than not, metal and wood are not the only materials used in manufacturing. Many industries also require the use of tubes and pipes for their products. This is where specialised equipment like tube and pipe benders come into play.

These machines are used to bend and shape metal tubes and pipes according to specific requirements. They are commonly used in industries such as plumbing, HVAC (Heating, Ventilation, and Air Conditioning), automotive, and furniture manufacturing. Tube and pipe benders have greatly improved the efficiency of these industries by providing precise bends in a fraction of the time it would take manually.

Material Handling Equipment

These days, it’s not just about producing goods but also about moving them from one place to another. This is where material handling equipment comes in. These machines are designed to efficiently handle and transport various materials, from raw materials to finished products.

Material handling equipment includes a range of machines such as forklifts, cranes, conveyors, and pallet jacks. They play a crucial role in streamlining the production process by making it easier to move materials around the factory floor.

In addition, material handling equipment also improves workplace safety by reducing the risk of injury from manual lifting and carrying heavy loads. They also help in optimising storage space and inventory management, leading to cost savings for manufacturing businesses.

Cutting and Measuring Tools

There’s no doubt that precision and accuracy are crucial in manufacturing, especially when it comes to cutting and measuring materials. This is where specialised tools such as callipers, micrometres, and laser cutters come into play.

Callipers and micrometres are used to accurately measure the dimensions of various parts and components to ensure they meet the required specifications. Laser cutters, on the other hand, use high-powered lasers to precisely cut through a variety of materials such as metal, plastic, and wood.

These cutting and measuring tools are essential for quality control in the manufacturing process, ensuring that all products meet the required standards. They also help reduce waste and improve efficiency by producing precise cuts and measurements. Even small errors in measurement or cutting can result in significant issues down the production line, making these tools essential for any manufacturing business.

Machine Tool Accessories

Maintaining and upgrading equipment is an ongoing process in manufacturing. This is where machine tool accessories come into play, providing additional features and functionalities to improve the performance of machinery.

Some common machine tool accessories include drill bits, cutting tools, and chucks. These accessories can be used for various purposes such as drilling holes, shaping materials, and holding workpieces securely in place during machining processes.