Laser printers (cutters) are amazing tools that give you the possibility to turn your ideas into reality. From engraving detailed graphics into wood to creating simple boxes or complex 3D objects, a 3D laser printer can be one of the best investments you can make if you’re a DIY enthusiast or someone who likes to create things. If you’re looking to buy your first 3D laser cutter, there are many things you need to take into consideration in order to get the best model for your budget. 3D laser cutting is a completely different process from conventional 3D printing, and it involves a computer-controlled machine which uses a laser beam to cut or engrave materials with great precision. Lasers are basically highly amplified and focused lights, causing materials to melt, burn or vaporize. The type of material a laser can cut depends on the machine’s power and the type of laser.

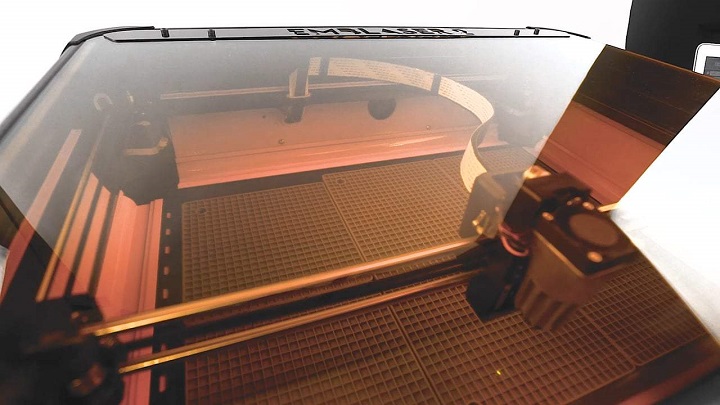

There are various different types of 3D laser printer models, but the most commonly used ones by hobbyists and small businesses are CO2 and gas lasers. Other types include crystal and fiber lasers, which are mostly used for heavy-duty industrial applications. Gas and CO2 lasers are capable of engraving and cutting a variety of non-metallic materials, including paper, wood, textiles, leather, and acrylic. The laser beam is created inside a tube that’s filled with CO2 gas, and with the help of mirrors and lenses, the beam is directed to the laser head and focused on the surface of the material being cut. The shape is defined by an input file which can be either a vector or raster image.

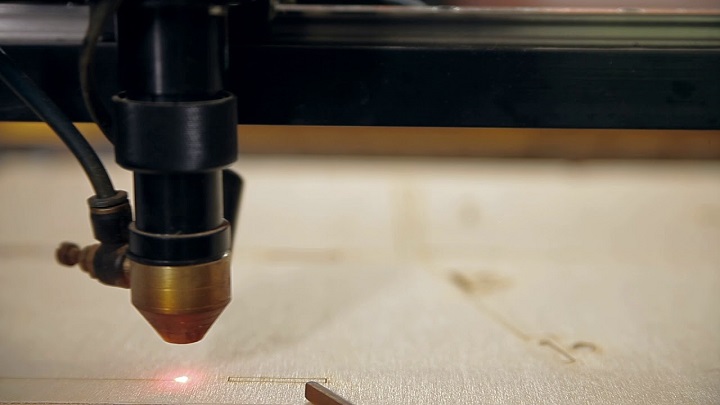

Generally, there are three basic tasks that a 3D laser printer can perform: cutting, engraving as well as marking. Cutting is when the laser goes all the way through the material and creates a cut. Laser cuts are typically precise and clean, and the look of the cut edges will vary depending on the material. For instance, edges of cut wood are darker brown than original timber, whereas the edges of acrylic don’t change colour and have a glossy finish after the laser cut is performed. The kerf of laser cutters is rather small, and if you don’t know what kerf is, it’s the width of the groove made when cutting. This can vary from material to material and is dependent on the settings of the laser. For most materials, the kerf is somewhere between 0.05-0.5mm.

On the other hand, engraving is when the laser beam only removes parts of the top material but doesn’t cut all the way through it. And lastly, marking is when the laser doesn’t remove material but only changes its colour. Marking is usually used performed on metals, where a marking solution is applied on the surface of the metal, and after drying the marketing solution engraving is performed. The heat from the laser will bond the solution to the metal and create permanent marks.

If you’re new to laser cutting and want to test it before you buy your first 3D laser printer, you can probably find one in local makerspaces, which are collaborative workspaces for creating and learning. They generally have a range of equipment including 3D printers, 3D laser cutters, CNC machines, and soldering irons. The people at these makerspaces are typically helpful and they offer courses on how to properly use laser cutters. Alternatively, you can find them in schools, universities, and colleges.

However, if you’ve decided that you want to buy a 3D laser printer, you’ll notice that there are thousands of different models all of which vary in quality and features. The price range between models is big, with entry-level Chinese cutters being about $500, and professional-grade cutters costing $5 000 or more. The most important factor to consider when picking a laser cutter is the materials you’ll be cutting or engraving with it. Depending on the power of the laser and other specifications of the laser cutter you’re using, the max material thickness that can be cut will vary. The laser power of cutters is measured in Watts, and the typical range is between 30 and 120 Watt. Lasers with higher laser power than that are usually used in industrial application exclusively.

But there are also some materials that you can’t, or shouldn’t attempt to cut or engrave with a laser no matter what, due to the fact that they may create dust or toxic gases which can be harmful to your health and damage the cutter itself. These materials are carbon fibers, PVC, PVB, artificial leather containing chromium, Beryllium oxide, materials containing halogens, PTFE/Teflon, and materials containing phenolic resins or epoxy.

Finding the ideal settings for the material you’re cutting is key to making great cuts. Be prepared to go through a lengthy trial and error process, especially if you’re constantly working with different materials. Once you’re happy with the cutting results you’re getting, write down the settings so that you can refer to them for future use.